Here is the start of a redo of a 4000 lb Hyster. It had supposedly been rebuilt and was stored outside for the last 15 years.

We are missing a few parts but there are plenty of mouse droppings to make up for it.

Removed the cowl and rollbar and we are ready to check it out.

After looking in the engine it was decided to remove it for further checking because of the excessive rust garbage in the cooling system

There was also a lot of junk in the flywheel area.

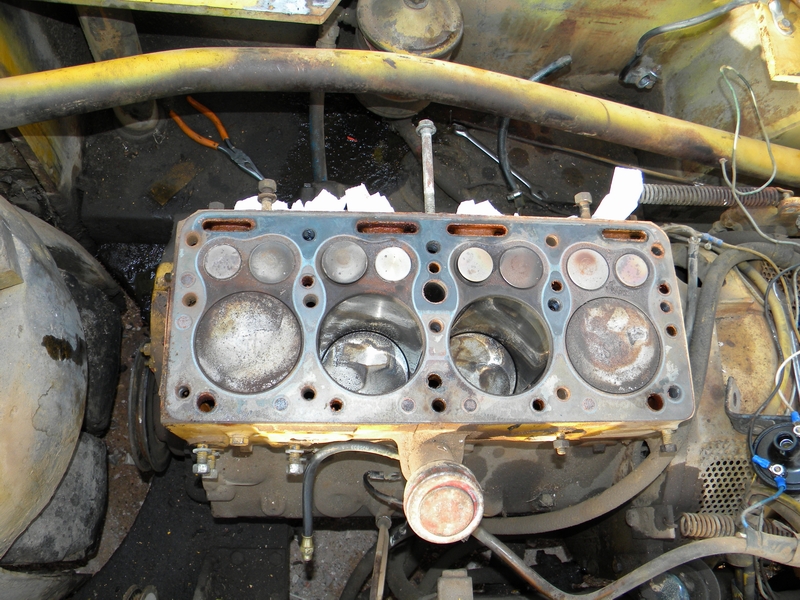

Popped the head first, doesn't look too bad.

Ready to pull, the book says split at the green arrow but I figured the blue arrow would be easier.

Came apart without too much of a problem.

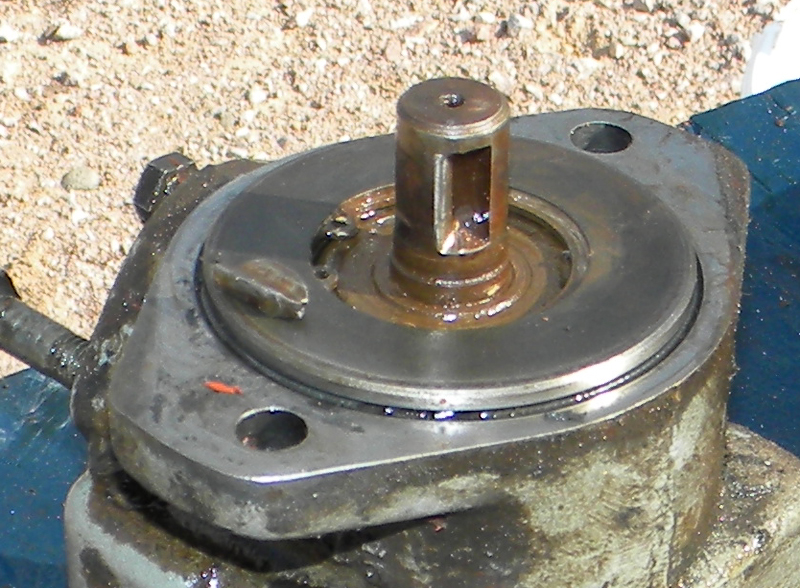

Found the keyway for the hydraulic pump badly worn from too small of a key.

Hydraulic unit out ready for cleaning.

Lots of room now with the fan and hydraulics out.

Brought the engine inside to work on.

Starting to lay out parts on the table.

Hydraulics, fan and tank hosed down.

Looks like there were new springs installed. Discarded the old fuel pump and blocked the hole. This unit was modified for propane.

Here's a shot of the water pump. Full of rust and garbage. Looks like they filled it with no antifreeze and left it to sit.

Set the engine on a stand for further checking.

The bottom end looks good with new pistons, rods and oil pump.

There was a lot of what appears to be moly grease in the pan from the assembly.

Went to pull the axles which did not feel right coming out.

The steering was pretty sloppy so off comes the counterweight.

Pulling the trans and differential to check for loose parts.

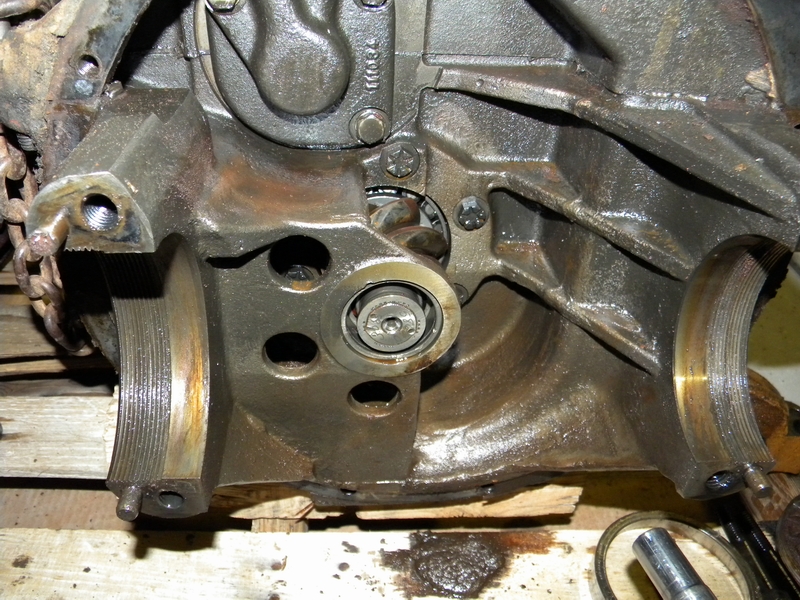

Took a while to figure out that these two bolts in the pumpkin had to be removed to release the differential.

The plot thickens. All kinds of junk in the differential housing.

Got the trans and diff out. Don't like all the rust.

Looks like the compartment could use a cleaning.

Got the diff and trans inside and ready for inspection.

Couple of pieces of metal loose inside.

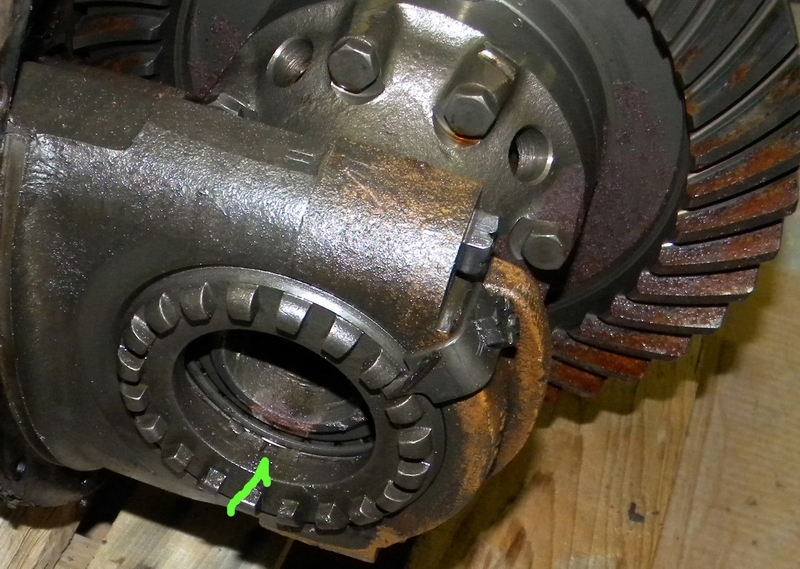

Here is a source of extra metal, no rollers in the pinion support bearing

End view of empty chassis.

OOOPS! This does not look good at all! Lots of nice aluminum shavings on the screen. Also a broken shim on left.

Here is the source of the shavings. The gear on the right shed some parts and chewed the aluminum ring.

Here is the gear. All of the bolts were finger tight and the 4 missing bolts were chewed up and lying in the bottom

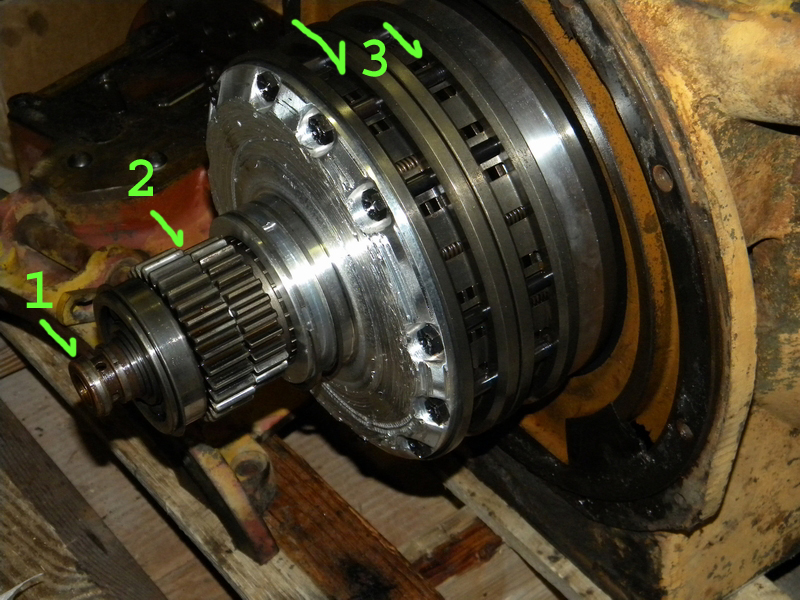

Here's a closer look at the clutch pack with the chewed aluminum plate. I think the broken bearing-shim belongs at location 2.

It looks like I'll need the ring seal (1), a new bearing shim (2) and 8 clutch plates (3). Not sure of the location of the shim.

Here is the disassembled unit.

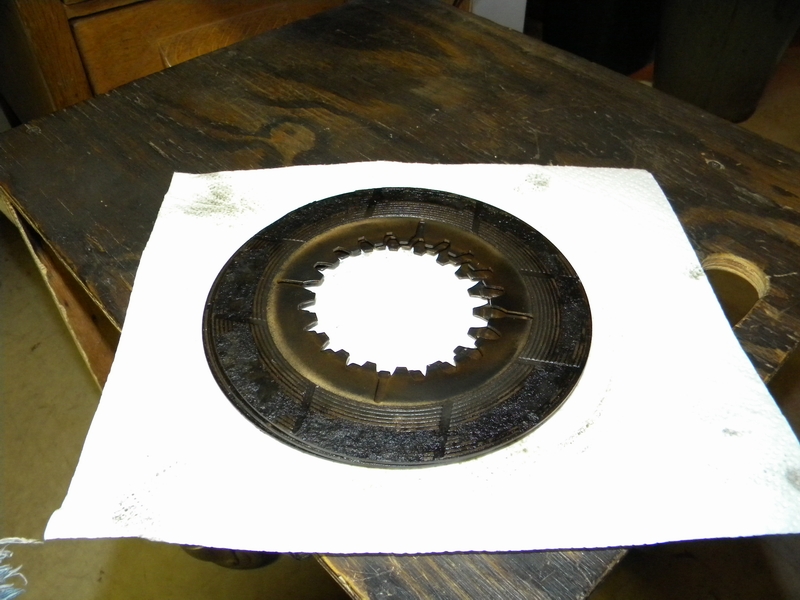

This is one of the better clutch plates. Note the lack of lining on the outer portion.

This is the front faceplate. That white powdery looking stuff is finely ground aluminum shavings.

After running around in circles looking for parts, I located a donor machine. It is an HE-50 with a taller boom and side shift.

The bad news: its in a soft backyard buried to the frame.

It's only supposed to get to 95 deg today so we went down to pick it up. Managed to clean the area and get it turned around.

Had to lay boards for the lift and for the truck

The original intent was to winch it up onto the trailer. That did not work.

A quick call and we went to plan B

Safe at home. Now to pull the trans.

The trans appears to be identical.

We found a 2" X ~3/4" dia chunk of broken spline in the differential but other than a few good nicks on the housing so far it looks good.